VDA-KLT container

When it comes to speed, precision, and standardization in automotive logistics, there’s no way around VDA-KLT containers. These standardized small load carriers are precisely tailored to the industry’s demands – from production to assembly, from storage to just-in-time delivery.

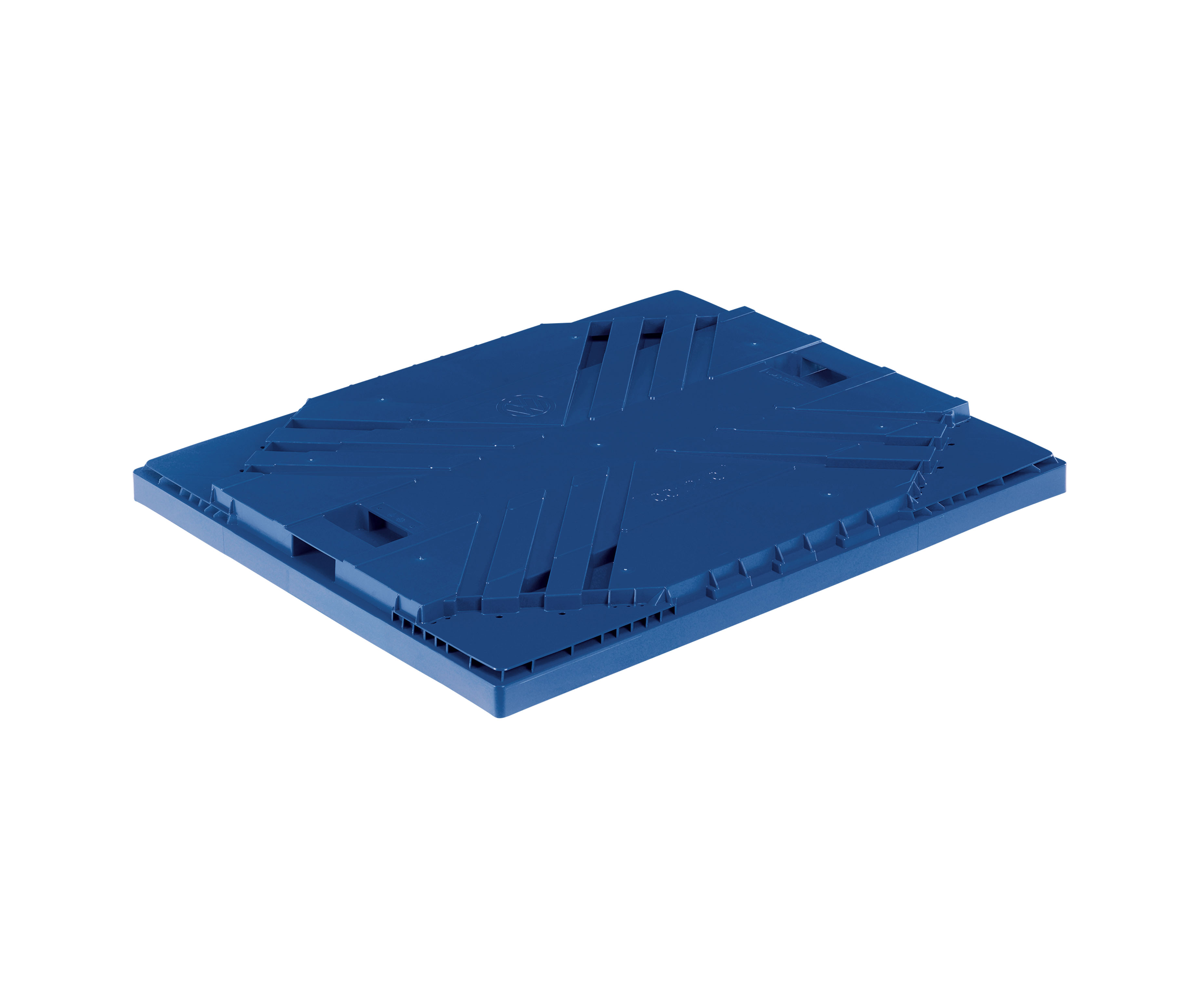

Within the VDA-KLT container family, the RL-KLT and R-KLT series offer distinct functional differences to suit a range of applications. RL-KLT containers feature smooth bases with integrated water drainage holes – ideal for automated washing systems. In contrast, VDA-R-KLT containers come with a robust composite base, reinforced by prominent stacking feet and a precision stack groove to ensure maximum stability in closed-loop systems.

VDA-KLT containers – the standard in the automotive industry

A VDA-KLT container is far more than just a plastic box – it’s a precision tool for logistics. Developed according to the stringent specifications of the German Association of the Automotive Industry (VDA), each of these small load carriers meets defined norms and the highest quality standards. Originally designed for the seamless material flow between car manufacturers and suppliers, VDA-KLT containers have long established themselves in other industries as well – wherever structure, stackability, and process reliability are essential.

VDA-KLT containers form the backbone of smooth parts logistics: they store, protect, and transport small components – from screws to sensors. OEMs and suppliers rely on three standardized base sizes: 300 x 200 mm, 400 x 300 mm, and 600 x 400 mm. All variants are tailored to fit Euro and industrial-sized pallets. These stackable KLT boxes integrate effortlessly into automated production environments. Their robust design withstands heavy loads and is optimized for robotic handling, gripper systems, and conveyor lines. Ergonomic handles and integrated label holders ensure ease of use and operational efficiency.

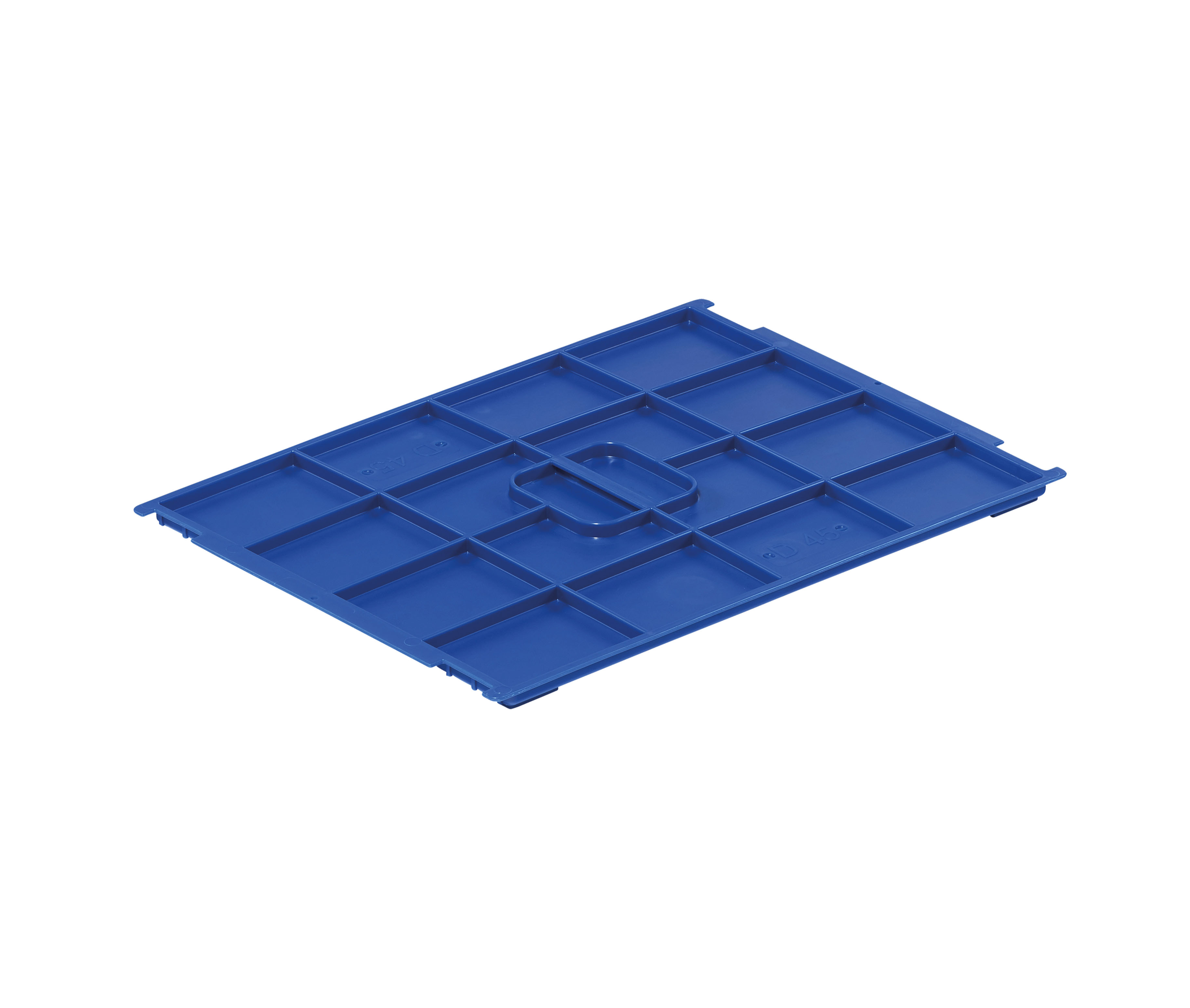

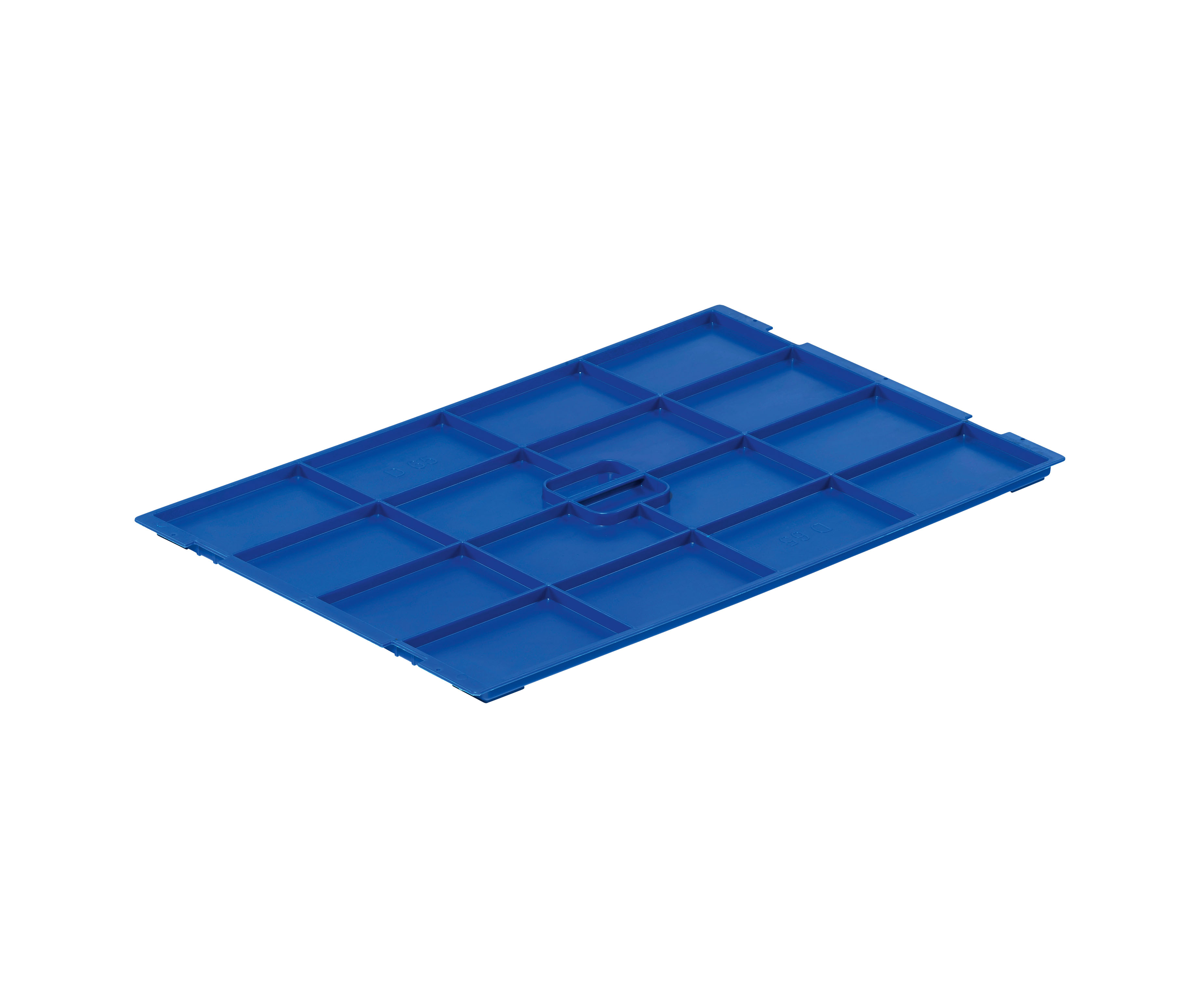

For the R-KLT and RL-KLT series, matching drop-on lids and protective covers are available – a system designed for secure storage and transport. Pallets and accessories are also perfectly coordinated. For sensitive electronic components, the ESD version is the right choice: all containers, lids, pallets, and covers are also available in conductive material to prevent electrostatic discharge damage.

VDA-KLT crate – recycling with guaranteed quality!

bekuplast makes the switch simple – from older C-KLT containers to the more efficient R-KLT and RL-KLT series. The best part: discarded containers are recycled, conserving resources and cutting costs. A sustainable move that combines economic and environmental responsibility.

Following VDA recommendation 4500, bekuplast fully closes the material loop: decommissioned VDA C-KLT containers are recycled through a process certified by SKZ Würzburg. The result? New R-KLT and RL-KLT containers that reintegrate seamlessly into existing logistics workflows – sustainable, cost-effective, and fully compliant with standards.